NEW OR CHANGED

3800 Series II Supercharged 3.8L V-6 (L67)

2004 Model Year Summary

· New Application in Chevrolet Impala and Monte Carlo

· Powdered Metal Connecting Rods

· Ultra-Fast Oxygen Sensors

· PO4+ Powertrain Control Module

· Direct-Mount Air Conditioning Compressor for Impala and Monte Carlo

· Improved Sealing

· Improved Accessory Belt

· Improved Starter

· 5W-30 Engine Oil

· Changes for Common Assembly with new Series III V-6

FULL DESCRIPTIONS OF NEW OR CHANGED FEATURE

NEW APPLICATION IN CHEVROLET IMPALA AND MONTE CARLO

The supercharged 3800 Series II SC will be offered as an option in the 2004 Chevrolet Impala and Monte Carlo. The Series II is no longer available in the Pontiac Grand Prix, which is equipped with the new 3800 Series III (RPOs L26 and L32) for model year 2004

POWDERED METAL CONNECTING RODS

The 3800 Series III has new hot-forged powdered metal connecting rods. Powdered metal is more durable and reliable than conventional cast iron, delivering greater anticipated life. As importantly, the powdered metal rods are stiffer than the cast iron parts they replace. That increases the resonant frequency of the rod and translates to lower vibration amplitude, meaning an overall increase in engine smoothness.

ULTRA-FAST OXYGEN SENSORS

Oxygen sensors on the 3800 Series II SC have greater heating capacity – 8.5 watts for the front sensor and 7.5 watts for the rear, compared to 6 watts in 2003. Increased wattage allows the sensors to achieve their most efficient operating temperature more quickly. The new sensors are also pulse-width modulated, allowing the PCM to manage them at variable heating rates, rather than with a basic on-off switch.

The oxygen sensors are located where the exhaust manifold runners meet, before the catalytic converter in the engine's exhaust stream, and after the catalytic converter in the exhaust pipe. In effect, they measure emission levels going into the catalytic converter and emission levels coming out. Using readings from both sensors, the PCM manages various engine operations in a fashion that minimizes exhaust emissions. The new ultra-fast sensors allow the exhaust system to achieve this “closed loop” operation in matter of seconds, monitoring oxygen levels before and after the catalytic converter for maximum emissions reduction.

PO4+ POWERTRAIN CONTROL MODULE

The 3800 Series II SC is managed by a new Powertrain Control Module. GM’s P04+ PCM adds software capability to manage the new oxygen sensors. Moreover, the Series II PCM is now common with that used on the GM’s 3100 and 3400 60-degree V-6 engines (RPOs LG8 and LA1). Such common parts reduce corporate inventory, streamline procurement practices and contribute to a common objective every automobile buyer understands: more efficiency in vehicle assembly plants and lower cost for a better product, which ultimately translates to more value for the customer.

DIRECT-MOUNT AIR CONDITIONING COMPRESSOR

The air conditioning compressor on 3800 Series IIs built for these applications bolts directly to the engine block, without struts or braces. This direct mounting considerably reduces vibration at the compressor and contributes to an overall reduction in noise, vibration and harshness.

IMPROVED SEALING

The 3800 Series II SC benefits from improved sealing technology developed for the new 3800 Series III. Improvements start with the rocker cover and oil pan gaskets, which are manufactured from an enhanced Elastomer material. The new gaskets provide better bead sealing and are more resistant to oil seepage for the life of the engine. Finally, the rocker cover gaskets are designed to enhance the structural rigidity of the covers, thereby reducing overall engine vibration.

Other gaskets were optimized with the same attention to detail. The lower intake gaskets are manufactured from a new HNBR material, which is more resistant than the previous silicone material to long-term deterioration with exposure to engine coolant. These gaskets now have compression limiters that maintain appropriate gasket compression for the life of the engine.

IMPROVED ACCESSORY BELT

The accessory drive belt accommodates the new direct-mount AC compressor. Supplied by Conti Tech, the belt is validated to the same durability standard as that on the 2003 3800 Series II, but it was specifically developed for quieter operation, further reducing operational noise and harshness. The belt is manufactured of a new “EPDM’’ rubber compound which resists hardening and cracking that normally occurs with ozone exposure, extending the belt’s anticipated life well beyond 10 years.

IMPROVED STARTER

The 3800 Series II SC is equipped with a new starter introduced in conjunction with the switch to 5W-30 engine oil (below). This starter is validated to the same durability and performance standards as those used on previous 3800 V-6 engines, and it weighs 2.5 pounds less, trimming an equal amount from overall engine mass.

5W-30 ENGINE OIL

The recommended lubricant for the 3800 Series II SC is 5W-30 oil, rather than the 10W-30 in previous 3800s. With the lighter oil, the maximum change interval does not change. GM’s industry-leading Oil Life Monitor still calculates oil life based on a number of variables, including engine speed, operating temperature, load or rpm variance and period of operation at any given load and temperature, and then recommends a change when it’s actually needed, rather than by some pre-determined mileage interval. The owner’s manual in cars equipped with the 3800 Series II will continue to recommend an oil change at least once a year.

The change in lubricant was driven by efficiencies in the engine and near-universal availability of the new GF-3 standard engine oil.

GF3 uses a new refining process, and it contains a friction modifier, meaning that that at a given weight or viscosity, it's more resistant to breakdown with heat. The 5W-30 engine oil is more efficient in cold ambient temperatures. It creates less friction or fluid resistance when the engine is cold, requiring less cranking power and reducing fuel consumption during cold starts. The 5W-30 oil also reaches its most efficient operating temperature more quickly that 10W-30.

CHANGES FOR COMMON ASSEMBLY WITH NEW SERIES III V-6

Dozens of 3800 Series II parts have been changed to allow common assembly with the new 3800 Series III V-6s. The parts range from fasteners such as cylinder-head bolts to electrical connectors. Such commonality has further increased efficiency and quality at the 3800 assembly plant in Flint, Mich., which was already recognized as one of the most modern and productive engine plants in the auto industry.

OVERVIEW

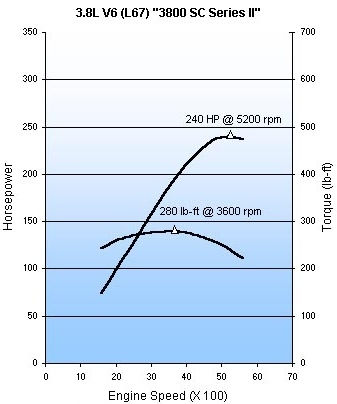

The 3800 Series II SC is the classic overhead-valve V-6 taken to a more powerful, refined extension. The Series II SC takes the cost, packaging and efficiency advantages of the 3800 Series II (RPO L36) and delivers torque comparable with competitive V8s. Since its launch in late 1991 for the 1992 Buick Park Avenue Ultra, the Series II SC has been enhanced in some fashion each model year. Virtually every system and component has been analyzed and improved for better performance, economy or durability.

The Series II SC achieved Low Emissions Vehicle (LEV) status in 2001—one of the first V-6 engines so certified. In 2002, the Series II SC became one of the first engines to employ iridium spark plug technology. These plugs have an iridium core that improves combustion efficiency for maximum fuel economy and minimum emissions.

The 3800 Series II SC’s specific output is surpassed by few overhead-valve engines anywhere, and its acceptance by customers has meant steadily increasing applications. The durable, highly refined design of the standard 3800 Series II allows most major engine components, including block, crankshaft and cylinder heads, to be used for the Series II SC without modification. Its 90-cubic inch supercharger is very compact; its housing includes the throttle-body adaptor, crankcase ventilation plumbing, coolant passages and the rotor drive mechanism. The drive mechanism is sealed and permanently lubricated, obviating the need for oil connections and eliminating a potential source of leaks. Performance has been further enhanced by refining engine-control software. The Series II SC delivers power in smooth, linear fashion, with virtually no supercharger lag, by adding boost at predetermined points along the power curve.

This supercharged V-6 engine’s success stems from continuous refinement and improvement, and one basic principal: customers care more about real-world performance, fuel economy and efficiency than they do about the specific technologies that produce that performance.

More info 09-29-04

Two powerful variations on one

impressive theme. Its standard version offers the largest engine displacement

in its class,* translating to impressive engine

output at low rpms — as well as minimal engine noise and fuel consumption.

Standard on GT, with 200 hp/230 lb-ft torque, no entry-level car in its class

has more horsepower. The Supercharged V6 elevates output to 260 hp/280 lb-ft

torque, making it the leader of its class.

![]()

EPA estimated mpg 20 city, 30 highway (GT); 18 city, 28 highway (GTP); 18

city, 27 highway (Comp G)

|

The new "Gen 5" Eaton Supercharger

is a segment exclusive. In fact, Grand Prix remains the only vehicle in its

class serious enough about power to offer a supercharged model.*

A belt driven by the crankshaft turns its interleaved impellers, which, in

essence, work as an air pump. This harnesses a tremendous surge of air through

the GTP's V6 engine — raising its performance considerably for a class-leading

260 horsepower.** While premium fuel is

recommended for maximum performance, it runs quite capably on regular unleaded

gasoline.

![]()